Tesla 4680 Cylindrical Cell Teardown and Characterization

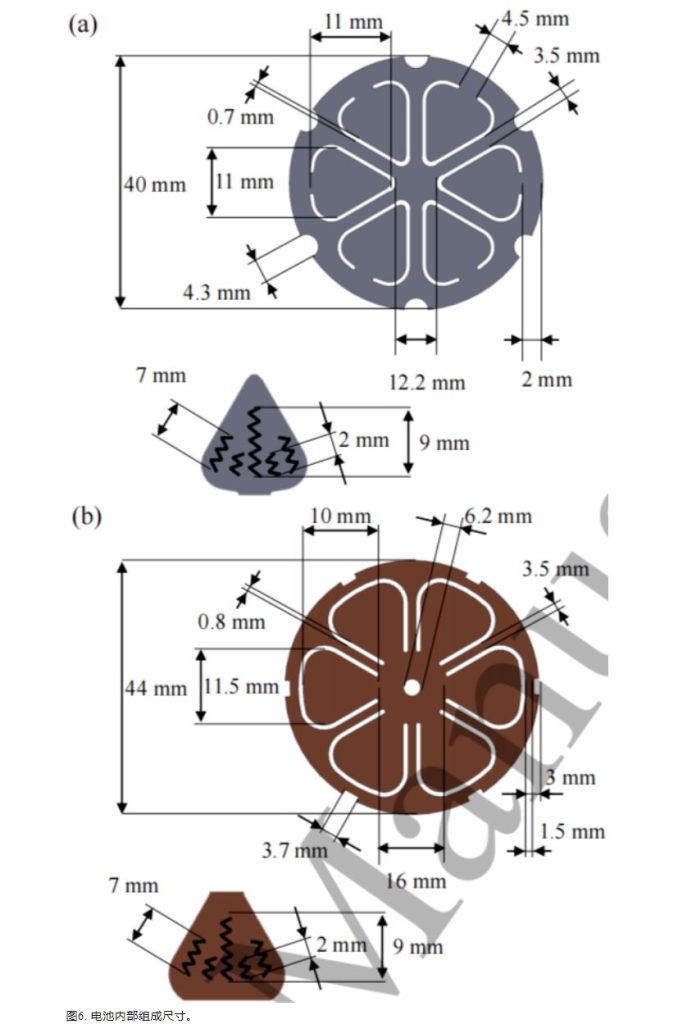

(a) Tabs.

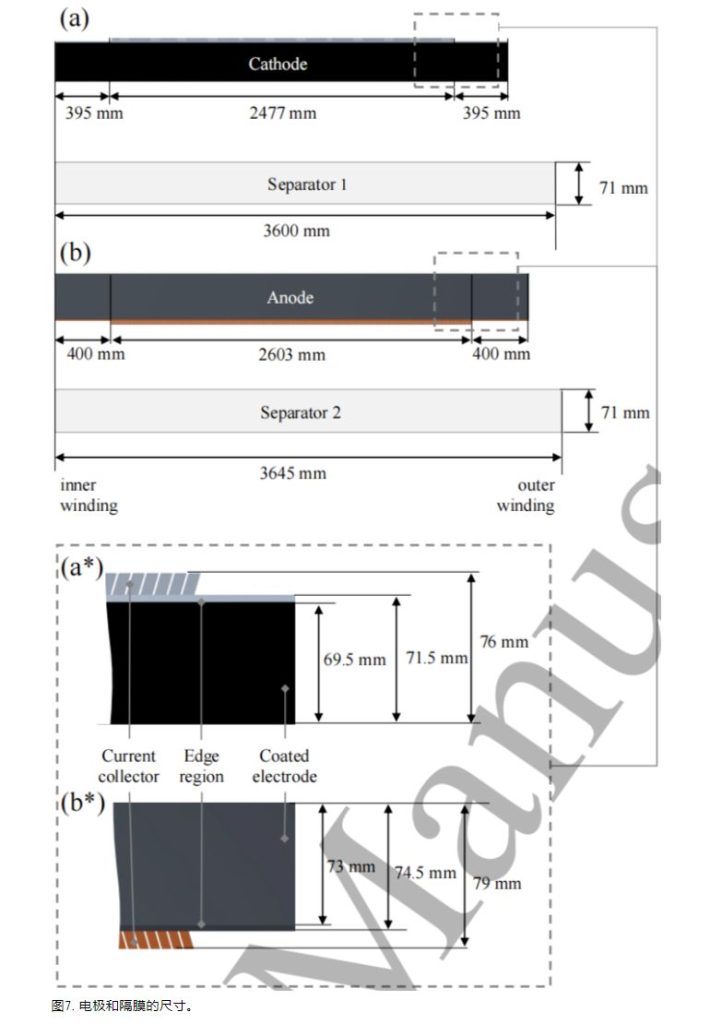

(b) Dimensions of the electrodes and separators.

(c) Dimensions of cathode and anode disk including a close-up of the leaf-shaped connectors with length and shape of the laser weldings. Drawings are not to scale.

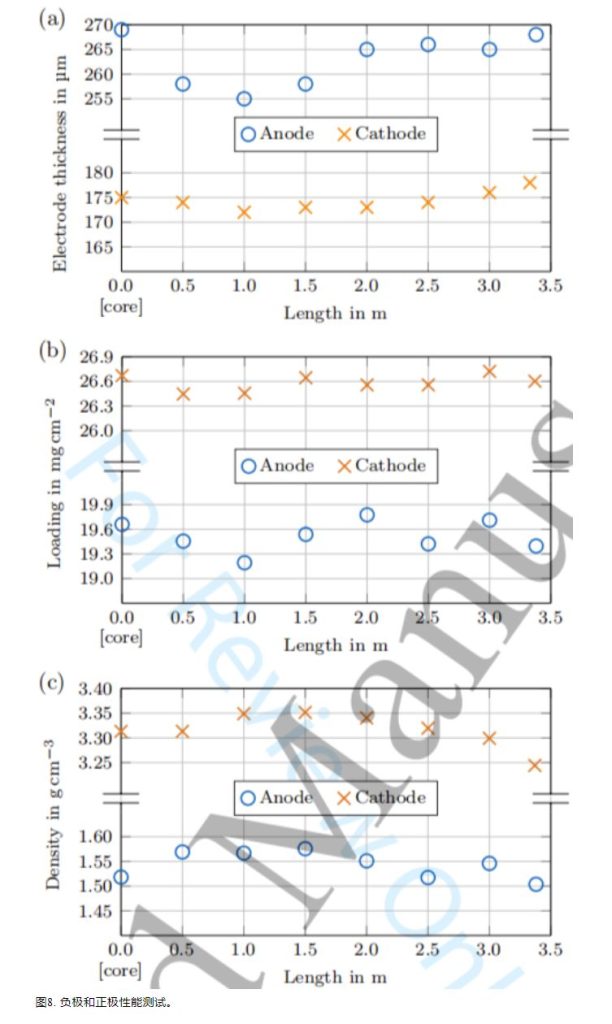

(d) Electrode properties over the full length of the anode and cathode sheet.

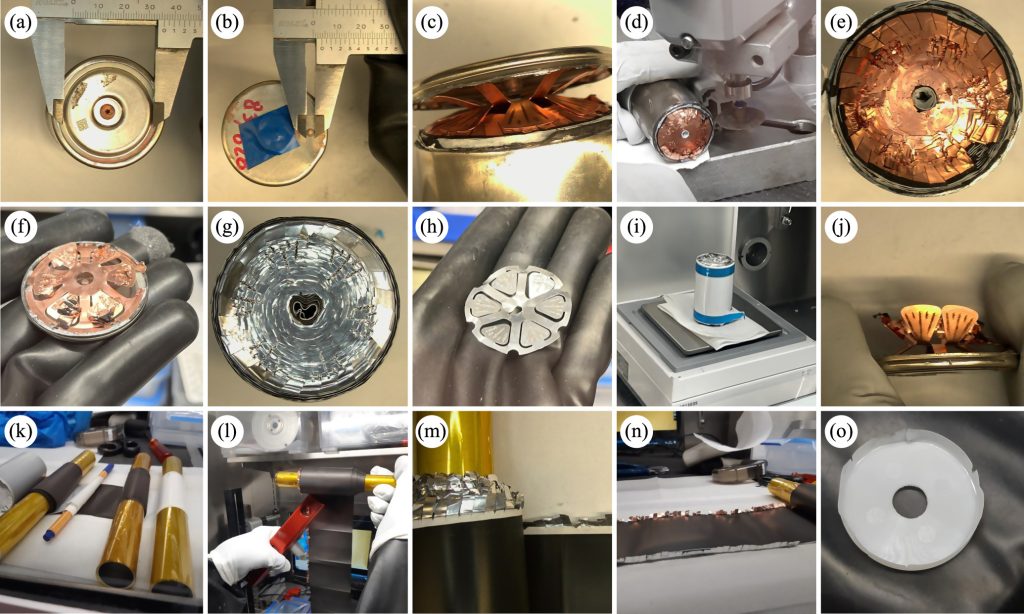

Battery research depends upon up-to-date information on the cell characteristics found in current electric vehicles, which is exacerbated by the deployment of novel formats and architectures. This necessitates open access to cell characterization data. Therefore, this study examines the architecture and performance of first-generation Tesla 4680 cells in detail, both by electrical characterization and thermal investigations at cell-level and by disassembling one cell down to the material level including a three-electrode analysis. The cell teardown reveals the complex cell architecture with electrode disks of hexagonal symmetry as well as an electrode winding consisting of a double-sided and homogeneously coated cathode and anode, two separators and no mandrel. A solvent-free anode fabrication and coating process can be derived. Energy-dispersive X-ray spectroscopy as well as differential voltage, incremental capacity and three-electrode analysis confirm a NMC811 cathode and a pure graphite anode without silicon. On cell-level, energy densities of 622.4 Wh/L and 232.5 Wh/kg were determined while characteristic state-of-charge dependencies regarding resistance and impedance behavior are revealed using hybrid pulse power characterization and electrochemical impedance spectroscopy. A comparatively high surface temperature of ∼70 °C is observed when charging at 2C without active cooling. All measurement data of this characterization study are provided as open source.

Contributions

This characterization article extensively analyzes cylindrical 4680 lithium-ion cells from the so-called “first generation” that were extracted from a state-of-the-art Tesla Model Y (model year 2022, manufactured in Austin, USA). The following contributions are particularly noteworthy:

In-depth cell architecture and electrode material analysis: Detailed exploration of the cell architecture, analysis of the material composition using scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) and investigation of electrode properties over the full length of the anode and cathode sheet.

Three-electrode analysis: Assembly of 1/2” T-cells with gold wire as a reference electrode and subsequent investigation of anode and cathode characteristics using pseudo open-circuit voltage (pOCV) and galvanostatic electrochemical impedance spectroscopy (EIS).

Thermal investigation during charging: Analysis of the heat generation at cap, center and bottom of one cell’s can during charging rates of up to 2C utilizing a thermal imaging camera.

Electrical characterization of several cells: Extensive performance characterization at the cell level using constant current (CC) charges/discharges and galvanostatic electrochemical impedance spectroscopy (EIS) measurements of multiple cells.

Hybrid pulse power characterization of one cell: Investigation of the resistance behavior of one cell using a hybrid pulse power characterization (HPPC) measurement employing 10 s charge and discharge pulses at C-rates of 0.5C to 1.5C in 10 % state-of-charge (SOC) increments from 10 % to 90 % SOC.

Open source provision of all measurement data: All raw measurement data, including cell teardown images, SEM/EDX recordings, and test procedures are provided as open source alongside the article.

Conclusions

This characterization study comprehensively examines the first-generation Tesla 4680 cylindrical lithium-ion cells from a state-of-the-art Tesla Model Y both at the cell level using electrical and thermal investigations and at the component level by means of a cell teardown to address the dearth of transparency in automotive lithium-ion cell development and production. Several cells were electrically characterized using pOCV, EIS and HPPC methods. One of the cells was studied with respect to its temperature development during charging rates of up to 2C. Additionally, one cell was subjected to a complex cell teardown involving the determination of the material composition using SEM and EDX, the analysis of the cell architecture and the subsequent evaluation of three-electrode cells. The key findings in the respective domains can be summarized as follows:

Cell teardown: The anode and cathode disks of hexagonal symmetry of the tabless design can act like compensating elements or springs when connecting the jelly roll with the housing. The thickness of the casing is high in comparison to conventional cylindrical cells, which are not used as a structural component. The electrode winding consists of a double-sided coated cathode and anode as well as two separators, while no mandrel is present in the cell core. The electrode loadings remain almost constant across the electrodes, but the electrode thickness varies. Spherical active material particles were found for the cathode side, while the anode consists of flake graphite particles. EDX confirms the exclusive use of graphite as the active material, with no detectable presence of silicon. The utilization of PTFE could indicate a solvent-free anode fabrication method, while the primer between the coating and the copper collector coating strongly suggests the utilization of a solvent-free coating process. The three-electrode analysis reveals characteristic potentials for the identified cell chemistry and a full cell impedance spectra dominated by the anode.

Characterization at cell level: Using data of one cell, energy densities of 622.4 Wh/L and 232.5 Wh/kg are calculated, indicating a conservative design of this first-generation 4680 cells. The pOCV analysis (DVA and ICA) confirm a NMC811 chemistry and a pure graphite anode. HPPC measurements reveal a characteristic SOC dependency with resistance increases both in the low and mid SOC region. A relatively high surface temperature is observed during a 2C charge in a free convection setup—requiring an adequate cooling system in the battery pack assembly.

Overall, this characterization study highlights current developments regarding large-format cylindrical lithium-ion cells for electric vehicles and provides a fundamental basis for future industrial and academic research toward the optimization of lithium-ion battery performance.

More information: Tesla 4680 Cylindrical Cell Teardown and Characterization

PDF: Tesla 4680

Learn more about Neware Technology Limited