The Atomic Force Microscope (AFM) is a high-resolution scanning probe microscopy technique, jointly invented by Gerd Binnig, Heinrich Rohrer, and Calvin Quate in 1986. AFM operates by measuring the interaction forces between a sharp probe mounted on a microcantilever and the surface of a sample. This method allows for the detection of surface topography and physical properties of the sample at the atomic level.

The working principle of AFM

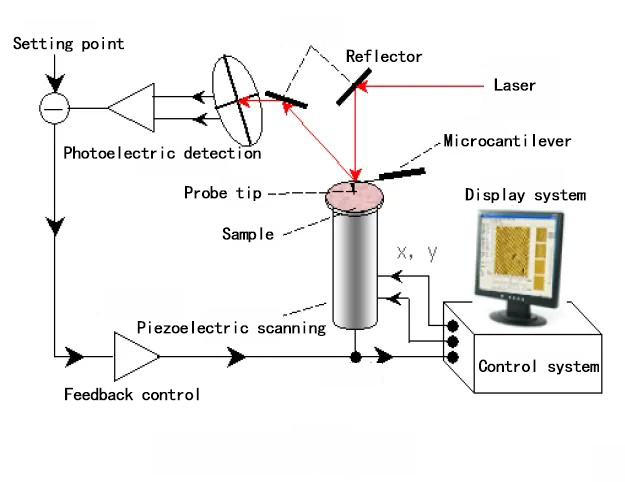

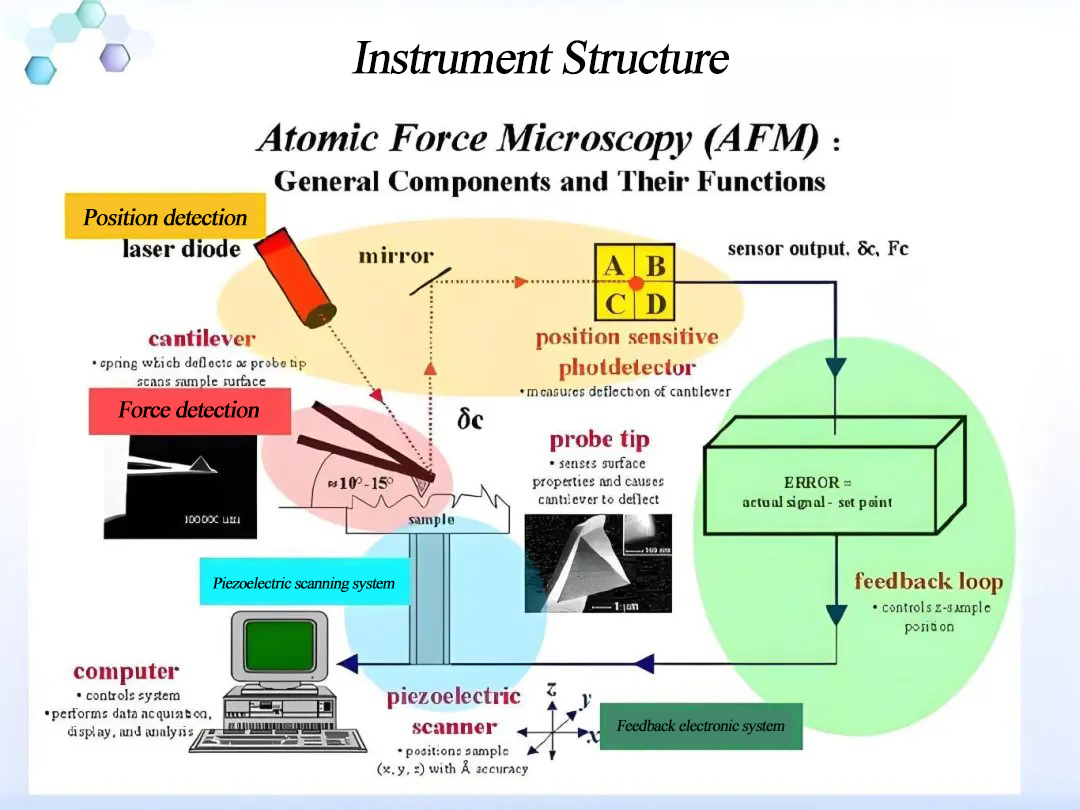

In an atomic force microscope (AFM), one end of a highly sensitive microcantilever is fixed, while the other end features a tiny probe tip that makes gentle contact with the sample surface. Owing to the extremely weak repulsive forces between the atoms at the probe tip and those on the sample surface, maintaining a constant force during scanning causes the microcantilever with the probe tip to oscillate vertically above the sample surface. This oscillation corresponds to the equipotential surface of the interaction forces between the probe tip and the sample atoms. By employing optical detection or tunneling current detection methods, the positional changes of the microcantilever at each scanning point can be measured, thus obtaining information about the sample’s surface topography.

The basic structure of AFM

The primary components of an atomic force microscope encompass the probe, probe positioning and scanning mechanisms, force detection sections, and feedback control units. The probe material is typically a harder metal, with tungsten wire being a widely used choice. Through processes such as electrochemical etching and focused ion beam milling, probes featuring a smaller tip radius can be produced.

The imaging modes of AFM

AFM has three basic imaging modes:

● Contact mode: The probe tip is in soft “actual contact” with the sample. As the tip gently scans across the sample surface, the contact force causes the cantilever to bend, thereby obtaining the surface profile of the sample.

● Non-contact mode: In non-contact mode, the tip vibrates above the sample surface without ever coming into contact with it. The detector measures long-range forces such as van der Waals forces and electrostatic forces that do not damage the sample being images.

● Tapping mode: In tapping mode, the tip vibrates at a certain frequency and amplitude above the sample surface, never coming into contact with it. The detector senses changes in the resonance frequency and amplitude of the tip’s forced vibration, thereby obtaining information about the sample’s surface topography.

The instrumental features of AFM

– **High Spatial Resolution**: AFM is capable of achieving atomic-level spatial resolution. Under optimal conditions, it can even reveal the arrangement and structure of individual atoms.

– **Non-Destructive Measurement**: AFM’s measurement process is non-destructive, meaning the sample remains unaltered or undamaged during the process. This is particularly crucial for studying delicate biological samples and soft materials.

– **Wide Sample Applicability**: AFM can be applied to a broad range of samples, including both conductive and non-conductive materials, as well as samples in solid and liquid environments, at room temperature and low temperatures.

– **Versatility**: AFM is not limited to topographic imaging; it can also measure mechanical properties (such as hardness and elastic modulus) and characterize electrical properties (such as conductivity and local potential).

– **Dynamic and Static Measurements**: AFM can perform both dynamic measurements (e.g., tapping mode) and static measurements (e.g., contact mode), making it adaptable to various measurement requirements and sample characteristics.

– **Environmental Adaptability**: AFM can operate under diverse environmental conditions, including high humidity, high temperature, low temperature, and various chemical atmospheres. This makes it highly valuable in materials science and industrial applications.

– **Simple Sample Preparation**: Unlike some characterization techniques that require complex sample preparation, AFM typically does not necessitate intricate sample processing.

– **Compatibility with Other Techniques**: AFM can be combined with other characterization methods, such as Raman spectroscopy and infrared spectroscopy, to provide more comprehensive sample information.

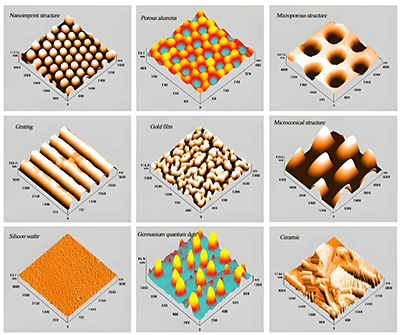

The typical morphology of AFM

AFM images of materials with large surface to volume ratio

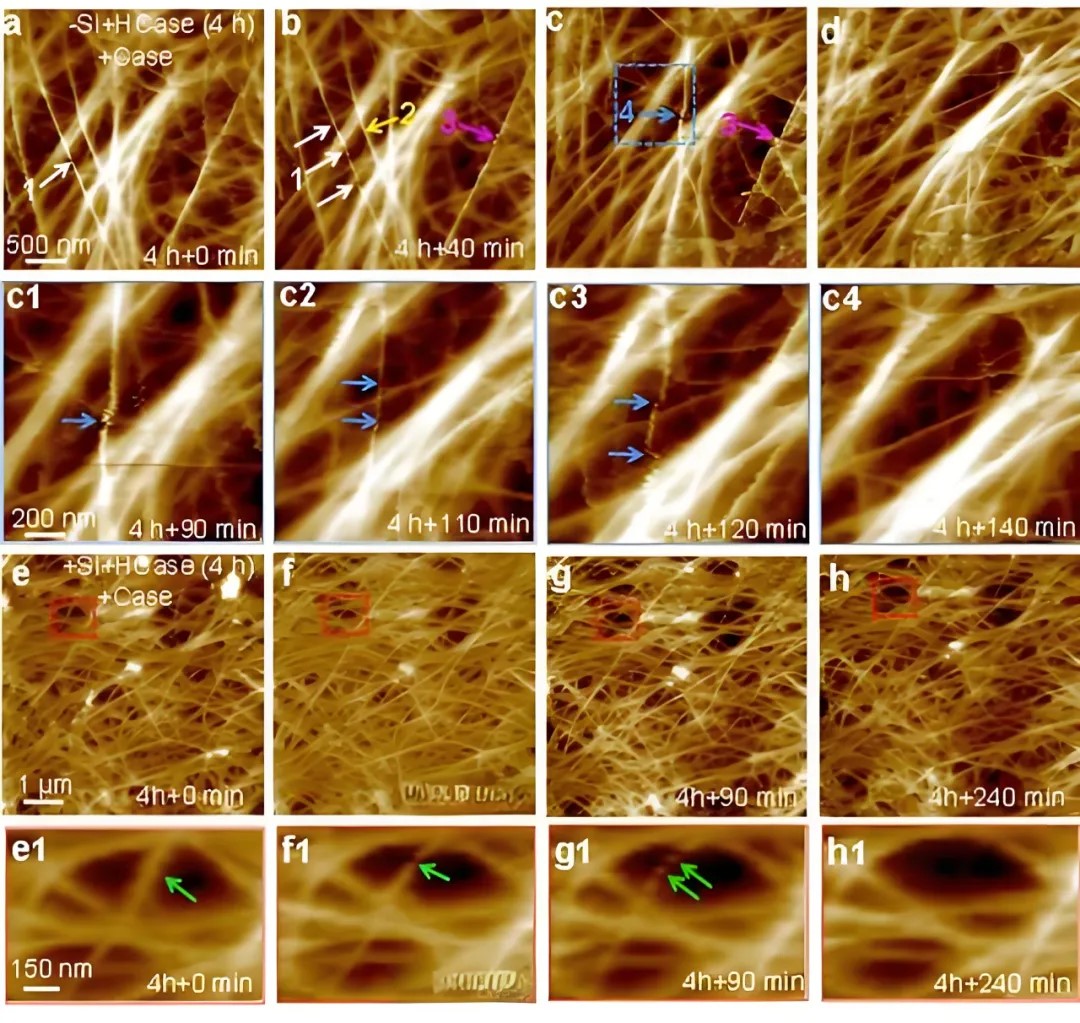

In situ AFM observation of cellulase

About Neware:

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.

If you do battery research or battery materials research, you might be interested in these products: