1.Research background and concept of prelithiation technology

With the advancement of technology and the development of society, energy consumption and environmental pollution problems are becomingmore and more serious, which has led to the pursuit of efficient and environmentally friendly energy storage solutions. Lithium-ion battery is one of the most mainstream energy storage devices, and its performance improvement has become a research hotspot.

However, traditional methods of enhancing electrode material performance and developing new electrolyte systems have faced limitations. During battery cycling, the irreversible loss of lithium ions severely impacts the energy density and cycle life of the battery. Previous methods for improving battery performance have struggled to meet the current demand for high energy density. As a result, prelithiation technology has emerged.

Prelithiation technology involves adding a small amount of lithium source to the battery system before charging/discharging. This compensates for lithium consumption during the battery’s charge/discharge reactions. To date, prelithiation technology is mainly categorized into three types: electrochemical prelithiation, chemical prelithiation, and the addition of sacrificial lithium additives.

2.Classification and introduction of prelithiation technology

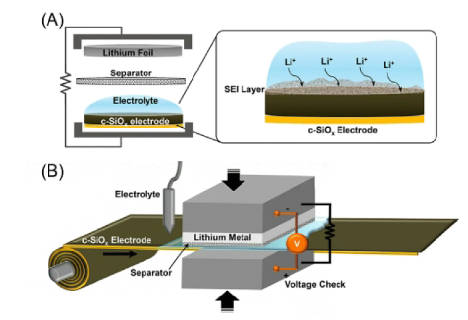

1.Electrochemical prelithiation: The prelithiation method for the cathode/anode of lithium-ion batteries is a promising approach to enhance battery performance. The core of this method is to complete the prelithiation of electrodes by controlling the depth of electrochemical charge and discharge. Specifically, electrochemical prelithiation involves creating a system consisting of lithium foil, electrolyte, and electrode. This setup allows lithium ions to actively diffuse through the electrolyte to the positive/negative electrode, completing the prelithiation process via an applied voltage. This method can be seen as a precise control version of the direct contact method with lithium foil, where parameters such as the degree and speed of prelithiation can be adjusted.

Electrochemical prelithiation can be categorized into two approaches: ex-situ and in-situ electrochemical prelithiation. For ex-situ electrochemical prelithiation, the electrode to be prelithiated is assembled with lithium metal into a half-cell. After undergoing a specific charge-discharge cycle, the electrode reaches the desired prelithiation level. Subsequently, the prelithiated electrode is combined with a new cathode/anode to form a complete battery. In contrast, in-situ electrochemical prelithiation necessitates the redesign of the lithium-ion battery. During assembly, lithium metal is introduced as a third electrode, and the prelithiation process is then carried out. Figure 1 illustrates the schematic diagram of electrochemical prelithiation.

Figure-1-The-schematic-diagram-of-electrochemical-prelithiation

2.Chemical prelithiation: It primarily encompasses chemical synthesis prelithiation, direct contact prelithiation, and chemical solution prelithiation. However, direct contact prelithiation and chemical solution prelithiation have garnered more extensive research and application.

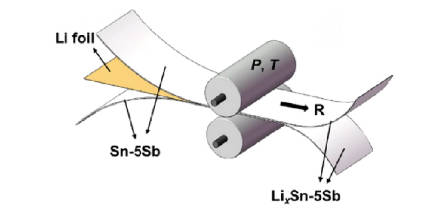

Direct contact prelithiation is mainly the prelithiation method for the anode of lithium-ion battery, that is, the electrode to be prelithiated is directly pressed and contacted with the lithium foil to complete the prelithiation process. While the process is relatively straightforward to execute, it still faces challenges such as the difficulty in precisely controlling the amount of pre-embedded lithium and effectively separating the lithium foil. Figure 2 illustrates the schematic diagram of direct contact prelithiation.

Figure-2-The-schematic-diagram-of-direct-contact-prelithiation

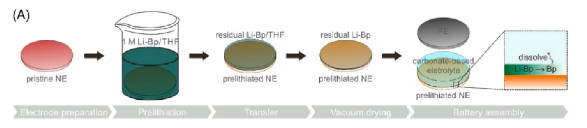

Chemical solution prelithiation involves using highly reducible lithium-containing solutions to treat electrodes, with active lithium being transported to the electrode material during redox reactions. In this method, most chemical prelithiation reactants are lithium-containing organic compounds, such as biphenyl lithium, naphthalene lithium, and butyl lithium. Chemical prelithiation can achieve relatively high uniformity, and the degree of prelithiation can be controlled by adjusting the treatment time, which is positively correlated with the prelithiation level. Therefore, its application scenarios are more extensive. Figure 3 illustrates the schematic diagram of chemical solution prelithiation.

Figure-3-The-schematic-diagram-of-prelithiation-of-chemical-solutions

3.Sacrificial Lithium-Compensation Additives

This approach entails incorporating lithium-rich additives into the positive or negative side of the battery. These additives undergo irreversible decomposition at the onset of the cycle, thereby releasing lithium ions to offset lithium loss within the battery system.

Based on their inherent characteristics, these additives are classified into two categories: positive-side lithium compensation additives and negative-side lithium compensation additives. These additives share several common characteristics and requirements, including:

(1) It has high irreversible specific capacity and low decomposition voltage;

(2) It has good air stability and safety;

(3) less decomposition residues, less gas output;

(4) It has good process compatibility and cost-effectiveness.

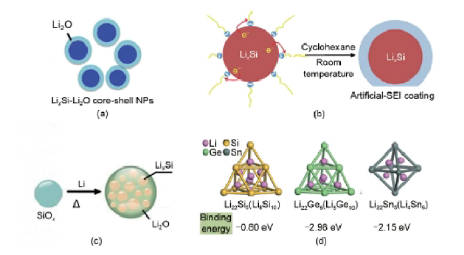

Based on the above characteristics, dozens of additives have been developed to meet different production needs. Figure 4 is the typical lithium compensation additive.

Figure-4-The-typical-lithium-compensation-additive

3.Case analysis of prelithiation technology

Given the existing classifications of prelithiation technology, a specific case will be selected for detailed introduction and analysis:

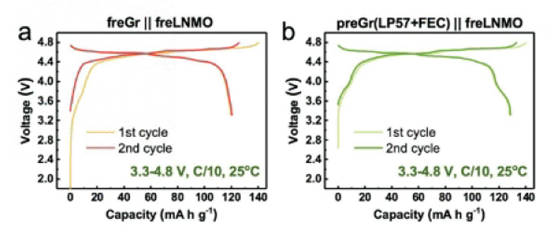

1.Electrochemical prelithiation: The prelithiation process typically involves assembling the electrode to be prelithiated with lithium metal into a half-cell, followed by electrochemical discharge (and subsequent cycling) to complete the prelithiation. After prelithiation, an SEI film forms with a certain amount of lithium embedded in the anode, which significantly enhances the reversible capacity and energy density of the subsequent battery. For instance, Figure 5 shows the constant current charge-discharge curves of both the original and prelithiated Gr||LNMO full batteries, demonstrating that prelithiation of the negative electrode markedly improves the initial discharge specific capacity of the full battery.

Figure-5-Comparison-of-charge-discharge-curve-of-full-cell-before-and-after-electrochemical-prelithiation

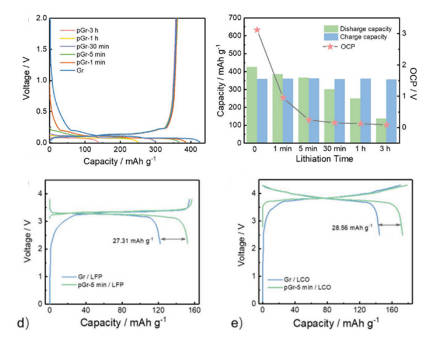

2.Chemical prelithiation: Taking chemical solution prelithiation as an example, this method typically involves preparing the solution, immersing the electrode, cleaning the electrode, and then assembling the battery. As shown in Figure 6, using Bp-Li-2MT solution as an example, the amount of lithium embedded in graphite and the coulombic efficiency in the first cycle can be effectively controlled by adjusting the prelithiation time (i.e., the immersion time in the solution). By using prelithiated graphite to assemble the full battery, the initial reversible capacity of the full battery has been significantly improved.

Figure-6-Comparison-of-the-effects-of-chemical-prelithiated-graphite

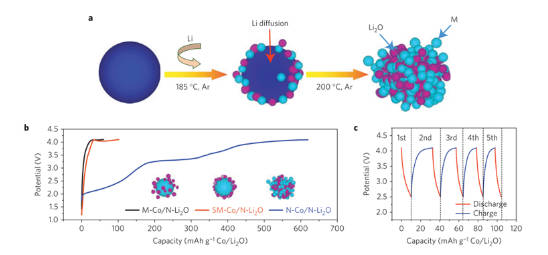

3.Sacrificial lithium-compensation additives: These additives are usually lithium-rich substances. So far, dozens of substances have been developed and successfully applied to the prelithiation system, such as lithium oxide, lithium nitride, lithium carbonate, lithium oxalate, lithium-silicon alloy, etc.

As shown in Figure 7, it is a Li2O-type lithium compensation additive. By adding a transition metal M to the additive, the decomposition voltage can be effectively reduced to complete the decomposition at a lower potential. The irreversible lithium ions released by the additive will compensate for the lithium loss during the battery cycle.

Figure-7-The-synthesis-diagram-and-test-result-of-M+Li2O-additive

4.Prospects for the development of prelithiation technology

As an important means to improve the performance of lithium-ion batteries, prelithiation technology has broad prospects for future development. First of all, with the increase of new energy demand, the application of prelithiation technology in the field of electric vehicles and renewable energy storage will be more popular, which will promote the further improvement of battery energy density and cycle life. Secondly, advances in materials science will promote the development of new electrode materials, such as lithium-containing compounds with high capacity and high stability, which will enhance the overall performance of the battery. At the same time, the introduction of process optimization and intelligent manufacturing technology can improve production efficiency, reduce production costs, and make prelithiation technology more competitive in commercial applications. In addition, research on environmentally friendly materials and processes will also become the focus of future development to meet the requirements of sustainable development. With the development of artificial intelligence and big data technology, the intelligent monitoring system will provide real-time data support for the prelithiation process to ensure the safety and reliability of the battery.

Based on the existing research content, the future development direction of prelithiation technology may focus on the following aspects:

1.Material innovation: Further research and development of new high-performance lithium-containing materials to improve battery energy density and cycle life;

2.Process optimization: Improve the current production process of prelithiation, reduce costs, improve safety and production efficiency, and ensure the feasibility of technology in large-scale applications;

3.Intelligent monitoring: develop a real-time monitoring system to track the state of the battery during the pre-lithiation process to ensure safety and stability;

4.Environmental friendliness: Explore green chemical methods to reduce the impact of prelithiation on the environment and promote sustainable development;

5.Application expansion: The prelithiation technology is applied to more fields, such as electric vehicles, energy storage systems and portable electronic devices, to meet the growing market demand.

If you do battery research or battery materials research, you might be interested in these:

Neware high and low temperature chamber