5 Useful Tips for Using NEWARE BTS

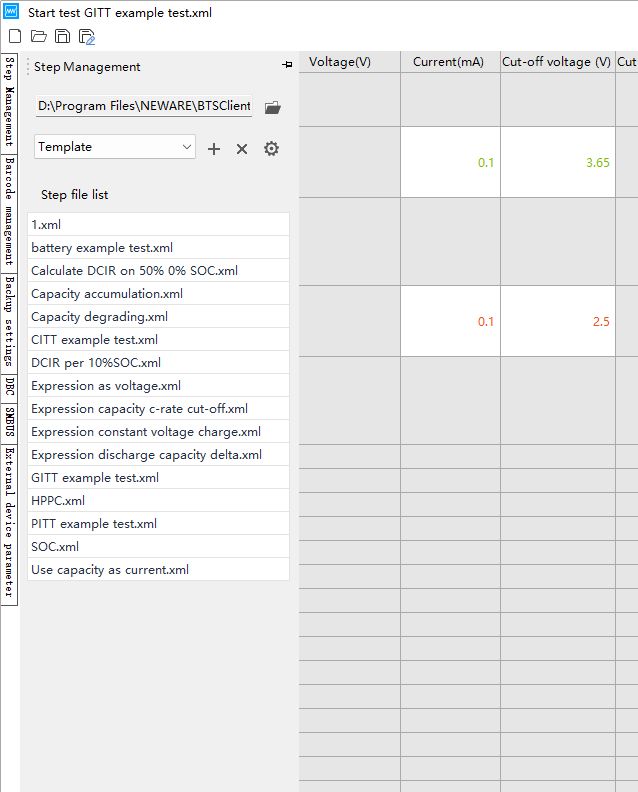

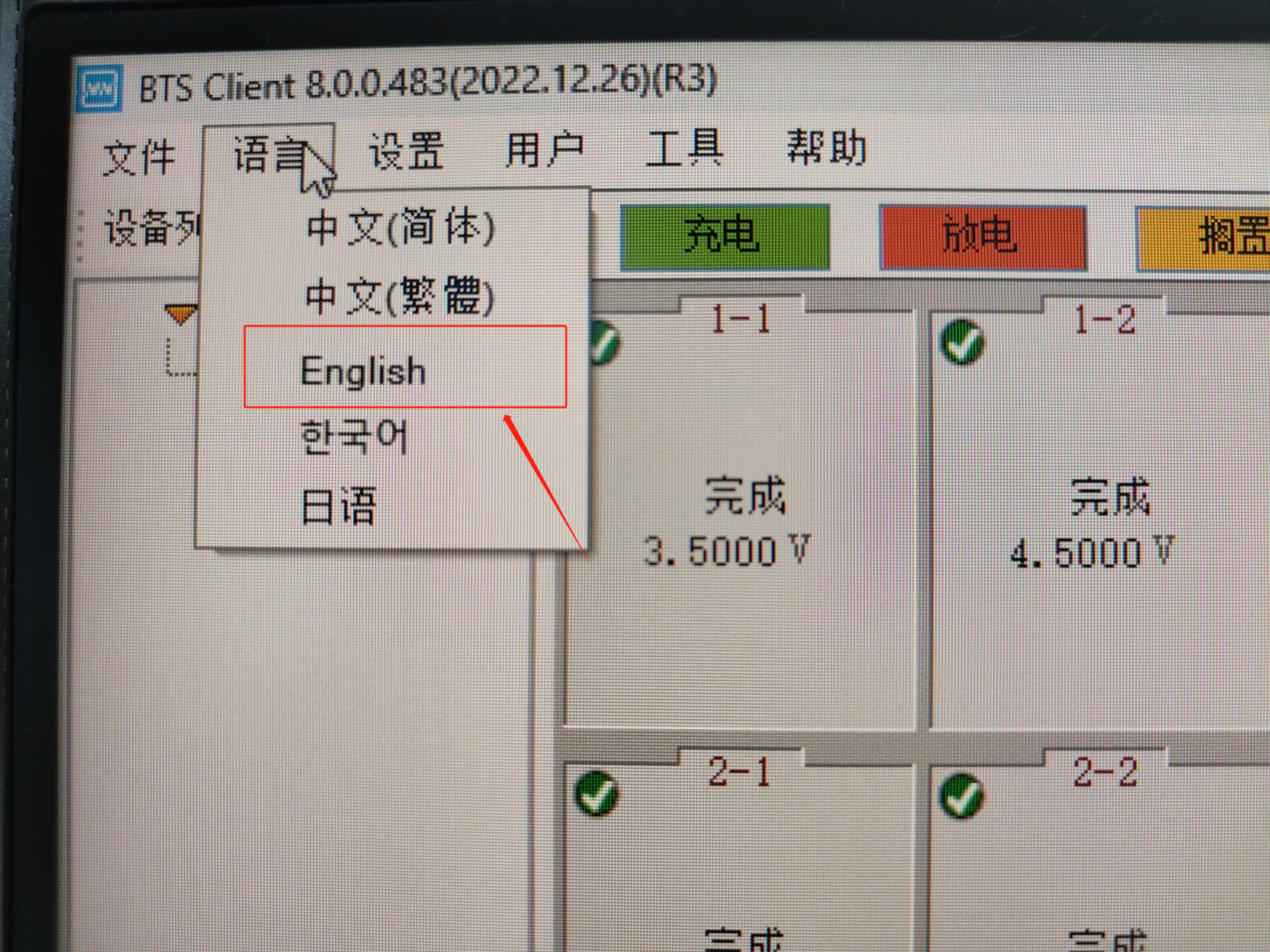

Are you proficient in using Neware’s software? Here are 5 useful tips on C-rate, dQ/dV, DCIR, etc. Set Language The second one is Language, Select English. How to set Fonts size and Icon size? Lower Right Corner C-rate setting if you need it “Set”——“System settings”——“Step edit”——find“C-rate” and “Cut-off C-rate” on the right——“〈”——Save In 4 zone, there are a lot of projects you can set up. Give it a try. Do you need dQ/dV? Select the channel, right-click, select the last one ” View data(D)”, find “Parameter settings” in the same place as the picture, “Recording Layer”, you will find” dQ/dV” “SOC/DOD”. There is a lot