Comprehensive Guide to Battery Testing: Understanding and Implementing Effective Test Methods

Battery testing is a critical process in the development and validation of high-performance, safe, and reliable battery systems. Whether for electric vehicles, renewable energy storage, or consumer electronics, rigorous testing ensures that batteries meet the required standards and perform optimally over their intended lifespan. This article provides a comprehensive overview of the test methods outlined in the draft white paper titled “Test methods for improved battery cell understanding,” which is a collaborative effort under the European Community’s H2020 Research Programme. The paper aims to enhance the understanding of battery cell behavior through standardized testing procedures.

Introduction to Battery Testing

Battery testing encompasses a wide range of procedures designed to evaluate various aspects of battery performance, safety, and longevity. These tests are essential for both research and development purposes and for ensuring that batteries meet industry standards and regulatory requirements. The draft white paper “Test methods for improved battery cell understanding” offers detailed insights into the methodologies and equipment required for effective battery testing.

Key Sections of the White Paper

Battery Cell Performance

Preconditioning Test: Ensures that the battery cells are stable and ready for further testing.

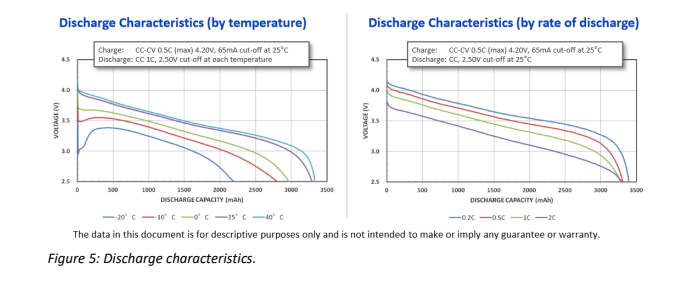

Standard Cycle: Measures the cell capacity at different rates and temperatures.

Capacity Test: Evaluates the cell capacity and energy content at various C-rates and temperatures.

Low C-rate Cycle: Provides low-rate voltage curves for battery modeling.

Constant Power Discharge Test: Assesses the battery’s performance under constant power discharge conditions.

Dynamic Stress Test: Simulates real-world driving conditions to evaluate battery performance.

Pulse Test: Analyzes the power capability of the battery under different conditions.

Thermal Characterization: Measures the heat distribution on the cell surface during operation.

Ageing Effects

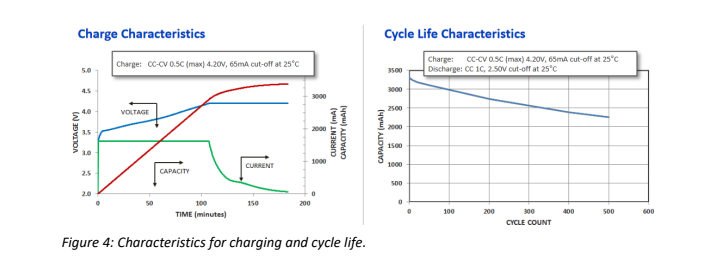

Cycle Life Test: Evaluates the battery’s lifetime under specific use conditions.

Drive Cycle: Links battery lifetime with driving distance by cycling batteries with realistic driving profiles.

Calendar Ageing Test: Assesses the battery’s characteristics after long storage periods.

Safety Aspects

Vibration and Mechanical Shock: Simulates the mechanical stress experienced by batteries in vehicles.

Drop Test: Evaluates the battery’s stability when dropped from a height.

Cell Impact and Crush: Tests the battery’s mechanical stability under crash conditions.

Penetration Test: Simulates short circuits within the cell by penetrating it with a conductive rod.

Thermal Tests: Includes temperature cycling, high-temperature endurance, and thermal stability tests to evaluate the battery’s response to extreme temperatures.

Importance of Standardized Testing

Standardized testing methods are crucial for ensuring consistent and reliable results across different laboratories and manufacturers. The white paper emphasizes the importance of using standardized procedures to evaluate battery performance, safety, and longevity. By adhering to these standards, researchers and engineers can compare results more effectively and develop better battery technologies.

Practical Applications of the White Paper

The test methods described in the white paper are applicable to a wide range of battery types, including lithium-ion batteries used in electric vehicles and renewable energy storage systems. These methods provide valuable data for battery modeling, safety assessments, and performance optimization. The paper also offers recommendations for specific test standards, making it a valuable resource for both academic and industrial researchers.

Conclusion

The draft white paper “Test methods for improved battery cell understanding” is a comprehensive guide to battery testing, offering detailed insights into the methodologies and equipment required for effective battery evaluation. By following the standardized procedures outlined in the paper, researchers and engineers can ensure that their battery systems are safe, reliable, and perform optimally over their intended lifespan. For those interested in delving deeper into the subject, the full white paper is available for download, providing a wealth of information and practical guidance on battery testing.

Download the White Paper

To access the full white paper and gain detailed insights into battery testing methods, visit the BatteryStandards.info website. This resource offers comprehensive information on battery testing standards and methodologies, making it an invaluable tool for anyone involved in battery research and development.

Detail: Draft White Paper Test methods for improved battery cell understanding Version 3.0

Neware was founded in 1998. We are trusted by ATL, BYD, CATL, Tesla, Apple, HUAWEI, SolarEdge, etc. We provide battery testing solutions for testing battery cell, module, pack, supercapacitor, BESS, etc. If you want to do capacity, cycle life, pulse, DCIR, GITT, HPPC, or EV driving simulation test, please feel free to contact us.